Internet of Things

By establishing an RFID system for improvements in consistency of information between plants,

logistics hubs, stores, and systems, our IoT aims to enhanced reliability of logistics flow and create

a foundation for continuous growth by securing accurate inventory management.

RFID Management System

(air-RFID)

Radio-Frequency Identification

air-RFID is an operation system with intelligent optimization. It collects data for monitoring, predictive control, and intelligent analysis and evaluation of possible anomalies by utilizing IoT/RFID in Smart Factories and Smart Logistics Management System.

Benefits of Implementation

| Work Task | Prior to Implementation | After Implementation |

|---|---|---|

| Production Orders |

|

|

| Production Inspection & Packing List |

|

|

| Inbound Logistics |

|

|

| Outbound Logistics |

|

|

| Inbound to Shops |

|

|

| Return from Shops |

|

|

| Location Check |

|

|

| Inventory |

|

|

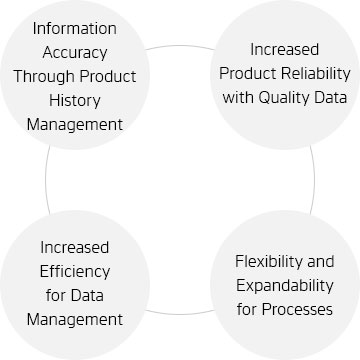

Benefits of System Establishment

For Logistics Center

- From manual to automated logistics management

- Seamless, advanced RFID I/O logistics system

- Prevention of inaccurate logistic information, loss of manpower and time

- Product management in conjunction with inventory management system

- Foundation for cutting-edge shop infrastructure

- Improved service with reduced work for sales personnel

- Confidence and sales opportunities between the shop and the head office

- Real-time information sharing between relational systems across the business

- Establishment of comprehensive monitoring system for quantity information

- Improve accuracy of inventory information by synchronizing information with actual products through real-time reporting between manufacturing plants, logistics centers, and stores

References

Hankook Tire & Technology

Hankook AtlasBX

Hankook Networks

Hanon Systems

Hansol Paper

AmorePacific

Taihan Electric Wire

Hankook Tire & Technology Global Youngone LF

Hankook Tire & Technology Global Youngone LF