MES

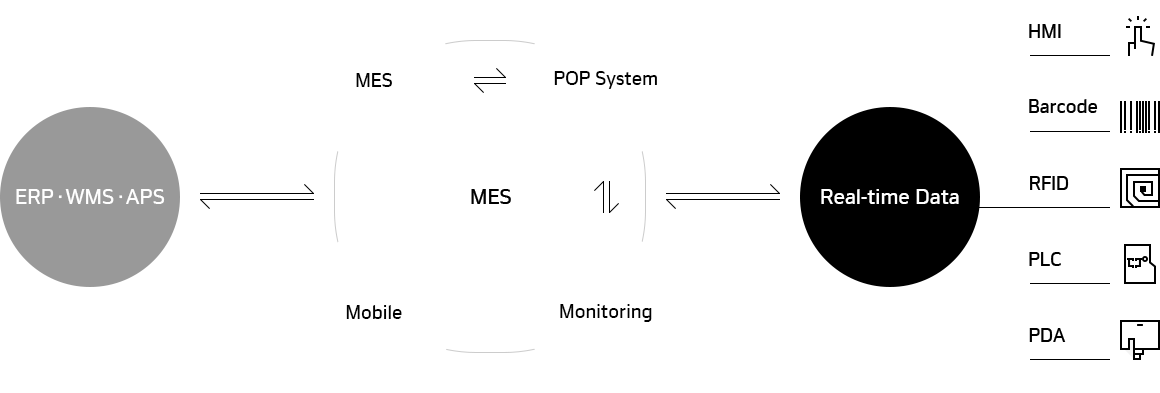

We connect all devices in your plant to provide process optimization

with manufacturing-related information in real time.

MES

Manufacturing

Execution System

(MES)

MES is a comprehensive manufacturing information system that actively contributes to the operation of your business. It is an integrated manufacturing information system in real-time that aggregates data across production from orders to final products in real time, provides statistical analysis data, and actively contributes to corporate management by supporting rational production (command, control) and quality innovation activities.

-

MES

- System management

- Master data management

- Manufacturing plan and work order management

- Manufacturing process management

- Logistics process management

- Traceability management

-

POP System

- Field management

-

Mobile

- Manufacturing process management

- Manufacturing performance management

- Inventory management

- Shipping management

- Announcements

- Emergency Contacts

-

Monitoring

- Urgent reports on manufacturing

- Process monitoring

- Announcements

- Welcome Board

Features

-

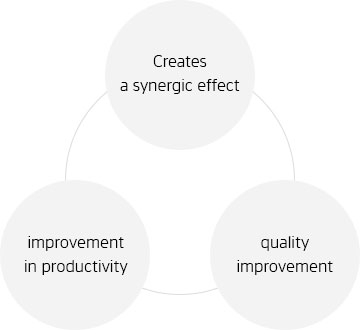

Realization of Optimized Manufacturing Management System

Creates a synergic effect via consolidation of relational systems

Realizes standardization of tasks and improvement in productivity based on systems

Realizes quality improvement through statistical quality management

Promises a flexible system in consideration of facility expansion

- Realization of Information-Oriented System

Promises competitive edge in product quality

Flawless synchronization with relational systems (ERP, WMS, APS)

Establishes a manufacturing planning system centered around delivery due dates

Promises reliability of field data (daily, monthly)

Provides a production-analysis function

- Contact Us

- ManagerKun Woo Kim

- kku2148@hankookn.com

- 031 - 5178 - 8375010 - 8260 - 4918

- Contact Us

- ManagerYun Jin Oh

- yunjin456@hankookn.com

- 031 - 5178 - 8376 010 - 8260 - 4492