MES

We connect all devices in your plant to provide process optimization

with manufacturing-related information in real time.

CMS

Predictive Maintenance for Facility Management

(air-CMS)Condition Monitoring System

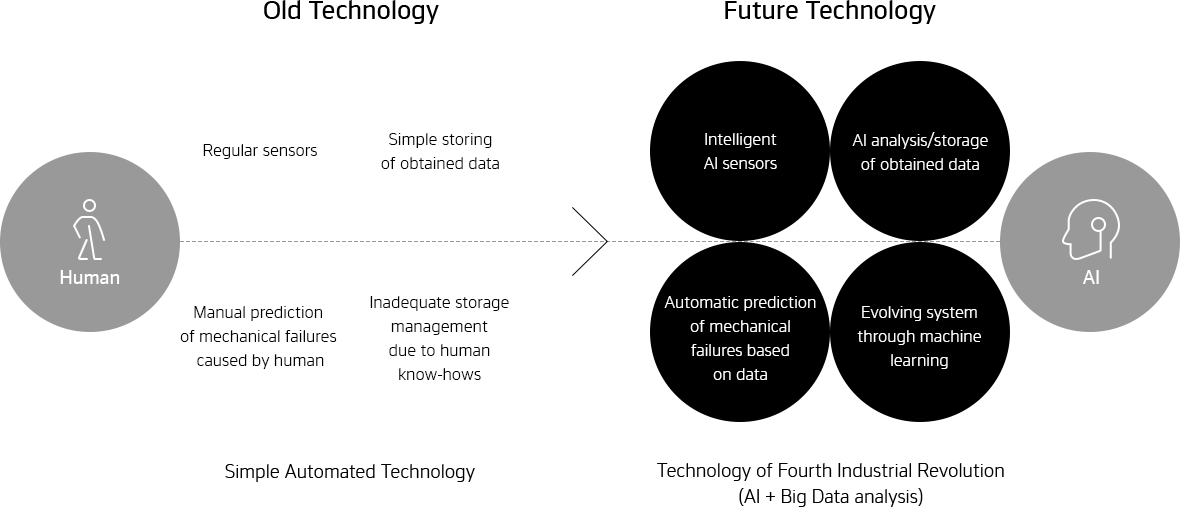

air-CMS is a tracking system jointly developed with KAIST as an industry-university collaboration project based on an existing, human-dependent prediction technology that analyzes and concludes mechanical failures. It operates on intelligent sensor modules and AI algorithms that reduce the system’s dependency on human and promise effective prediction technology for mechanical-failures.

System Configuration

Features

- Implements intelligent sensors, cloud, Big Data, AI (use of algorithms, machine-running, etc.), and security technologies

- More comprehensible display of information via various graphic visualization

- Provides information in an integrated dashboard design for quick response

- Offers systematic support with separate management and tracking for primary facilities

- Signal processing for vibration analysis (FFT, Trend, RMS, Envelope, etc.)

- Jointly-developed algorithm with KAIST

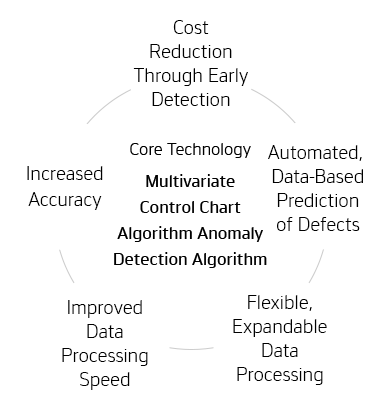

Benefits of the Implementation

- Improved accuracy through correlation between multiple sensors

ex) On-set date of defective parts (2018.07.09) Detection by existing system (2018.07.03) → detection by air-CMS system (2018.06.12) : Result of trial implementation at Company H: defects detected 15 days earlier than the existing system

- Automated, data-based (Big Data, Machine Learning) prediction of defects

ex) Defect detection by man → AI detection : Test result: 96.2% accuracy

- Reduction in cost to repair through early detection

- Flexible, expandable data processing

- Processing data at edges

- Improved data processing speed

- Differentiation and separate collection of meaningful data (into a faulty case library)

Core Technology

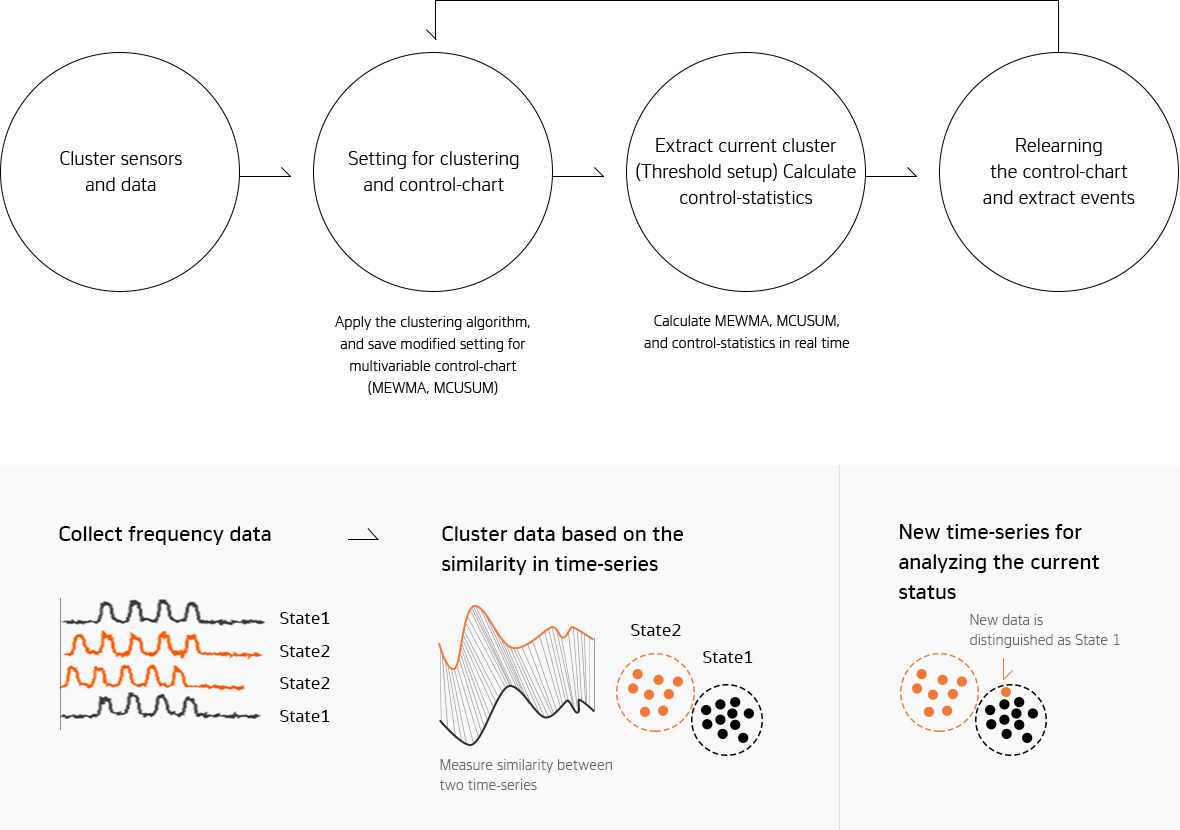

Multivariable Control-Chart Algorithm

Application of multivariable control-chart algorithms (MEWMA and MCUSUM, and early detection through management statistics of various clustered sensors (analysis of correction between multisensors.

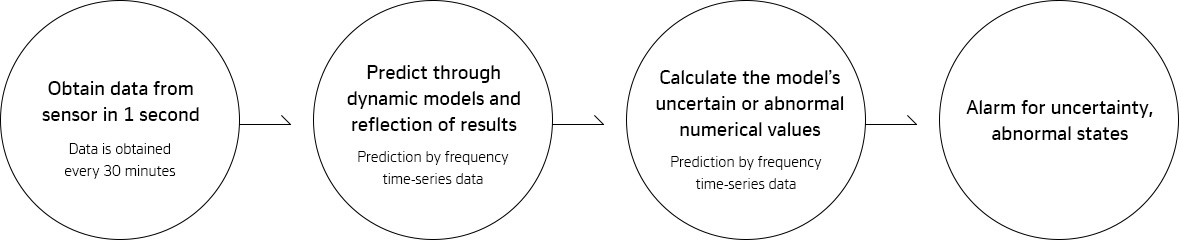

Data-based algorithm for detecting machine failures

As an intelligent prediction (frequency time-series) model through dynamic values from sensor data, it increases the accuracy of automatic prediction and detection of facilities.

- Contact Us

- ManagerKun Woo Kim

- kku2148@hankookn.com

- 031 - 5178 - 8375010 - 8260 - 4918

- Contact Us

- ManagerYun Jin Oh

- yunjin456@hankookn.com

- 031 - 5178 - 8376 010 - 8260 - 4492