MES

We connect all devices in your plant to provide process optimization

with manufacturing-related information in real time.

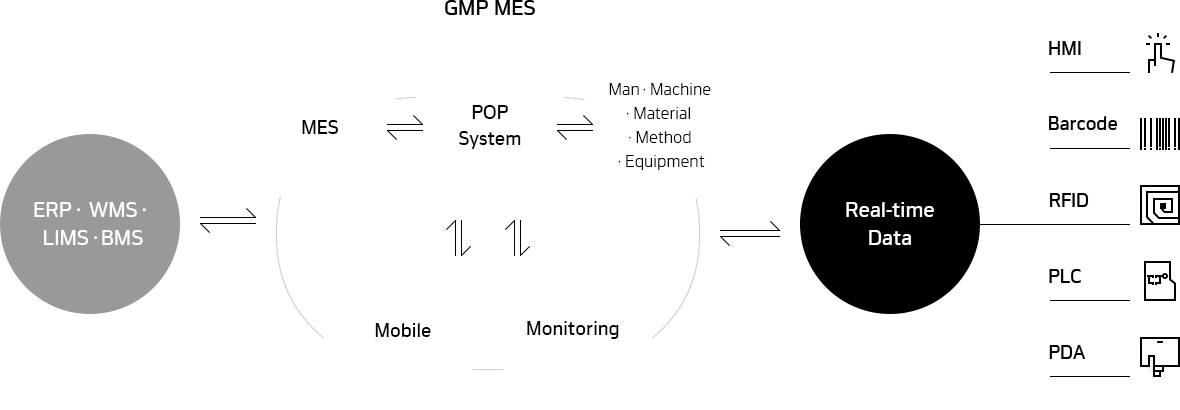

GMP MES

Good Manufacturing Practice Manufacturing Execution System

(GMP MES)

GMP MES is an execution system for good manufacturing practice. As a specialized MES solution against GMP-based regulation laws for pharmaceutical/cosmetic manufacturing, it contributes to your business’s operation by providing flexible actions against regulations on GMP and FDA21 CFR Part 11, satisfying the conditions for CSV (Computer System Validation), and strengthening your business’s competitiveness in both manufacturing and product quality.

-

GMP MES

- System management

- Master Data management

- Manufacturing records management

- Work order management

- Manufacturing process management

- Quality management

- Logistics management

- Traceability management

- Facility maintenance management

- Approval process management

- Annual quality evaluation management

-

POP System

- Electronic SOP management (weighing, manufacturing, packaging)

- Production performance management

- Personnel / facility management

- Raw material / material management

- Semi-finished product / work-in-process

- Carrying Container Management

- Notice

- Equipment connection S/W

-

Mobile

- Raw material / material management

- Raw Material / Warehouse Management

- Semi-finished product management

- Semi-finished product Warehouse Management

-

Monitoring

- Urgent reports on manufacturing

- Urgent reports on quality

- Facility operation

- Personnel in manufacturing

- Announcements

Features

-

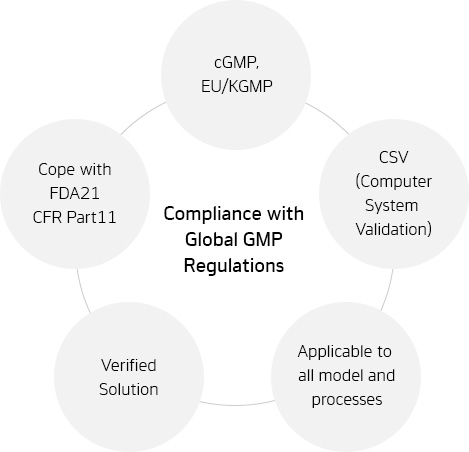

Compliance with Global GMP

Reliable management against globalization/advancement of GMP

-

Fulfills Requirements from FDA 21 CFR Part 11/CSV

Cope with CSV(Computer system validation)

-

Application to Various Product Groups and All Processes

Tool support for creation and simulation of electronic records and electronic signatures

Implementation to all manufacturing processes from loading raw material to packaging

Flexibility against definition and changes in work order

-

Consistency in Data and Flexible Reponses in Field

Automatic collection of recipe/parameter data from manufacturing facilities

Prompt response to expanding or redesigning processes/facilities

- Contact Us

- ManagerKun Woo Kim

- kku2148@hankookn.com

- 031 - 5178 - 8375010 - 8260 - 4918

- Contact Us

- ManagerYun Jin Oh

- yunjin456@hankookn.com

- 031 - 5178 - 8376 010 - 8260 - 4492